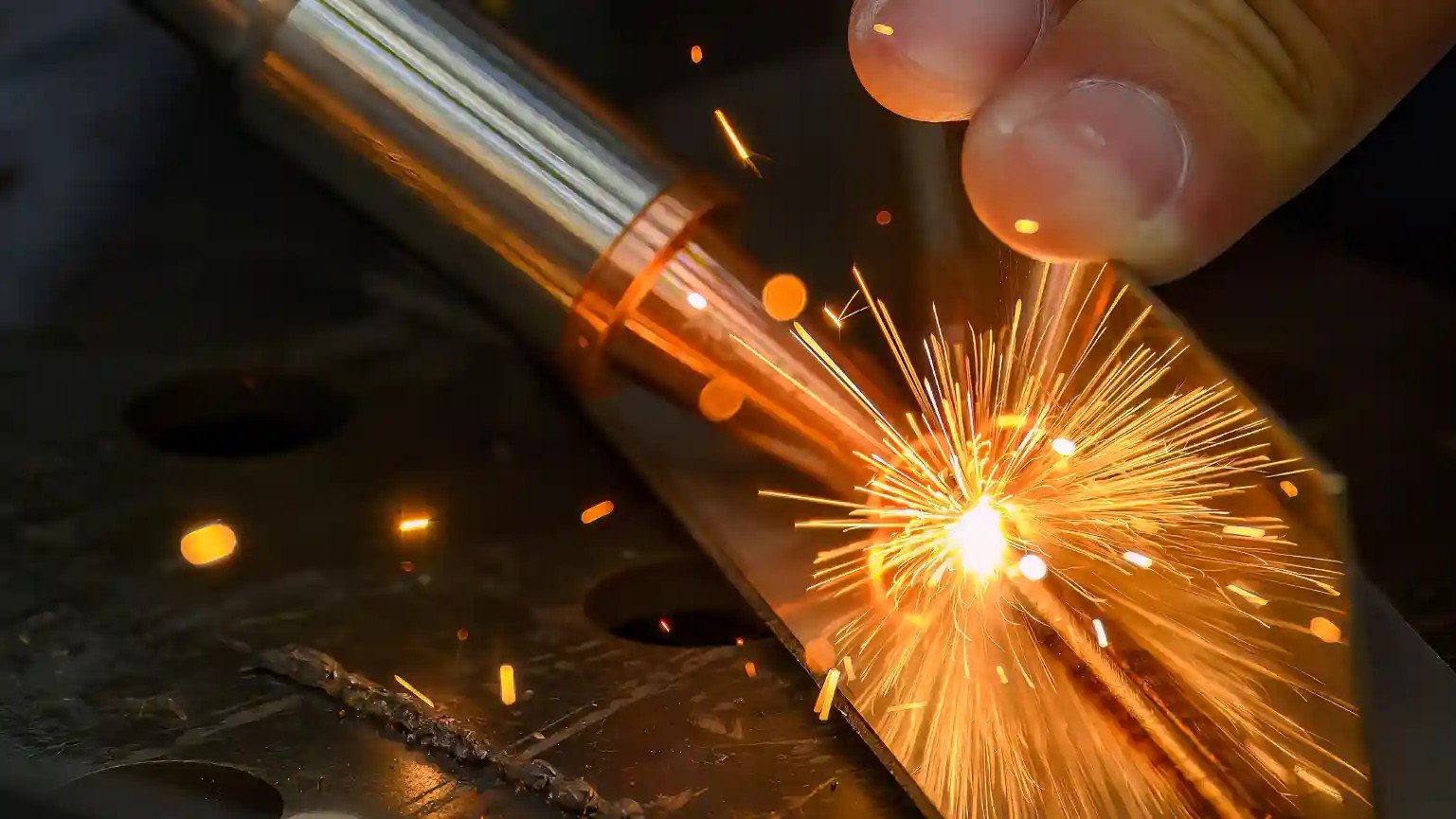

Advanced Laser Welding Services

Our state-of-the-art laser welding service delivers precision fusion welding with exceptional accuracy and minimal thermal distortion. Ideal for aerospace, automotive, and industrial applications requiring the highest quality welds.

What is Laser Welding?

Laser welding is an advanced fusion welding process that uses a high-powered, precisely focused beam of light to melt and join metals. Unlike conventional welding methods that rely on an electric arc or flame, laser welding delivers concentrated energy directly to the weld zone through a non-contact process. This results in exceptionally precise welds with minimal heat input to the surrounding material.

The laser beam can be focused to an extremely small spot—often less than 1mm in diameter—creating a highly localised melting zone. The rapid heating and cooling cycle produces strong, clean joints with very narrow weld profiles and heat-affected zones. This makes laser welding particularly valuable for precision engineering applications where dimensional accuracy and material integrity are critical.

At Efford Engineering, our laser welding capability represents a significant investment in advanced manufacturing technology. Combined with our ISO 9001:2015 certified quality management system, we deliver laser welding services that meet the demanding requirements of aerospace, automotive, medical, and industrial clients.

Benefits of Laser Welding

Laser welding offers significant advantages over conventional welding methods, making it the preferred choice for precision engineering applications.

Precision & Accuracy

Laser welding provides extremely fine control over the weld zone, with focused beam diameters as small as 0.2mm. This precision minimises the risk of damage to surrounding material and allows us to work on intricate assemblies, thin sections, and close-tolerance components where conventional welding would be unsuitable.

Minimal Heat Input

The concentrated laser beam creates a very small heat-affected zone (HAZ), dramatically reducing thermal distortion and warping. This is critical for maintaining dimensional accuracy on precision components and preserving the metallurgical properties of the base material.

Speed & Efficiency

Laser welding is significantly faster than conventional arc welding methods. The high welding speed, combined with minimal post-weld finishing requirements, reduces overall production time and cost while delivering superior results.

Clean, Quality Finish

The focused energy of laser welding produces neat, consistent welds with minimal spatter, oxidation, or discoloration. In many cases, little or no post-weld grinding or finishing is required, saving time and preserving component integrity.

Material Versatility

Our laser welding system can work with a wide range of metals including steel, stainless steel, aluminium, titanium, copper alloys, and more. Importantly, laser welding can join dissimilar metals that would be challenging or impossible with traditional welding methods.

Complex Geometries

The non-contact nature of laser welding allows us to reach areas that conventional welding torches cannot access. This makes it ideal for complex joint geometries, internal features, and assemblies where physical access is limited.

How Laser Welding Works

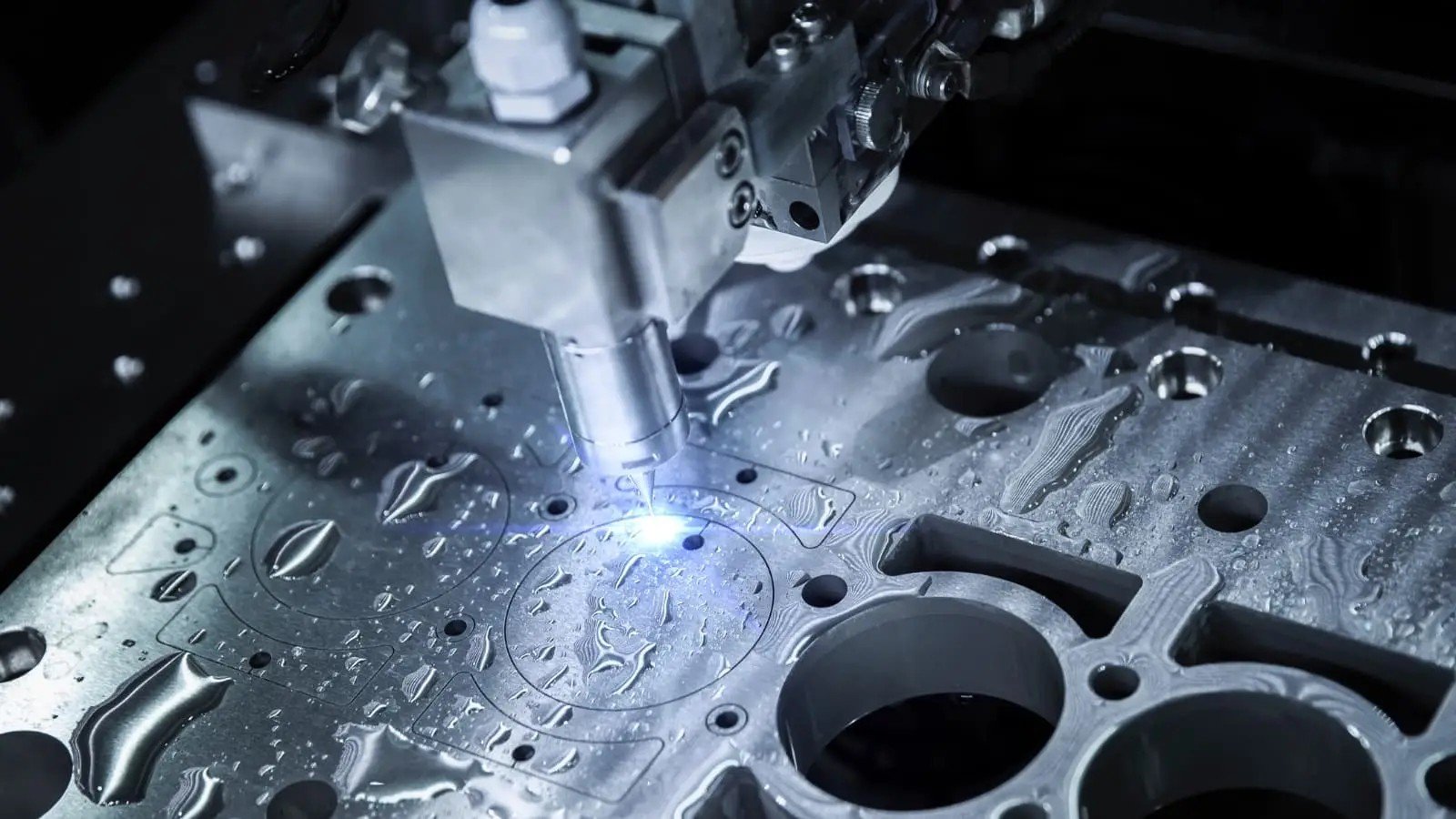

The laser welding process begins with careful preparation of the joint surfaces. Unlike some conventional welding processes, laser welding requires clean, well-fitted joints for optimal results. The components are positioned and clamped to maintain precise alignment throughout the welding operation.

During welding, the laser beam is focused onto the joint line through a series of optical elements. The concentrated energy rapidly heats the metal to its melting point, creating a molten pool that fuses the materials together. The laser beam is then traversed along the joint at a controlled speed, creating a continuous weld seam.

For deeper penetration welds, we use a technique called "keyhole welding" where the intense laser energy vaporises a small column of metal, allowing the beam to penetrate deep into the material. The molten metal flows around this vapour keyhole and solidifies behind as the beam moves forward, creating strong, deep welds with narrow profiles.

Depending on the application, we may use shielding gas to protect the molten weld pool from atmospheric contamination. We can also add filler wire for joints requiring additional material or where the gap between components needs to be bridged. All parameters—including laser power, travel speed, focal position, and gas flow—are carefully optimised for each specific application.

After welding, every joint is inspected to ISO standards using visual examination and, where required, additional NDT methods. This ensures that our laser welds consistently meet the quality requirements specified for each project.

Applications

Laser welding is ideal for a wide range of precision engineering applications where quality, accuracy, and minimal distortion are essential.

- Aerospace component repair and manufacture

- Precision instrument assemblies

- Medical device manufacturing

- Automotive component production

- Tool and die repair

- Thin-wall tubing and enclosures

- Sensor housings and electronics enclosures

- Hermetic sealing applications

- Dissimilar metal joining

- Mould and tooling repair

Materials We Weld

Our laser welding system is capable of joining a wide range of engineering materials, including dissimilar metal combinations.

Steel

Carbon and alloy steels for general engineering applications

Stainless Steel

All grades including austenitic, ferritic, and duplex

Aluminium

Various alloys with appropriate parameters for each

Titanium

Ti-6Al-4V and other aerospace-grade alloys

Copper Alloys

Brass, bronze, and copper with optimised settings

Nickel Alloys

Inconel, Monel, and other high-performance alloys

Why Choose Efford Engineering for Laser Welding?

At Efford Engineering, laser welding is our primary service and a core competency. Our investment in advanced laser welding technology reflects our commitment to providing industrial clients with the highest quality joining solutions available. Combined with our ISO 9001:2015 certification and UKAS-calibrated inspection equipment, we deliver laser welding services you can trust.

Our experienced team understands the science behind laser welding and the practical considerations that determine weld quality. We work closely with clients to understand their specific requirements, recommend optimal approaches, and deliver results that meet or exceed expectations.

- ISO 9001:2015 certified quality management

- UKAS-calibrated inspection of every weld

- Experienced laser welding specialists

- Fast turnaround for industrial clients

- Local service covering Devon and the South West

- Complementary machining and finishing capabilities

Need Precision Laser Welding?

Whether you need a strong seam weld on thick tubing or a delicate lap joint on thin sheet material, our laser welding delivers superior results. Contact us today to discuss your laser welding requirements and receive a competitive quotation.